The essential role of steel in the Railway Industry

The railway industry, a cornerstone of modern transportation, owes much of its strength and durability to steel. From the tracks that crisscross continents to the powerful locomotives that haul freight and passengers, steel plays a pivotal role in ensuring the efficiency, safety, and longevity of rail systems worldwide. Let’s dive into the multifaceted importance of steel in the railway industry.

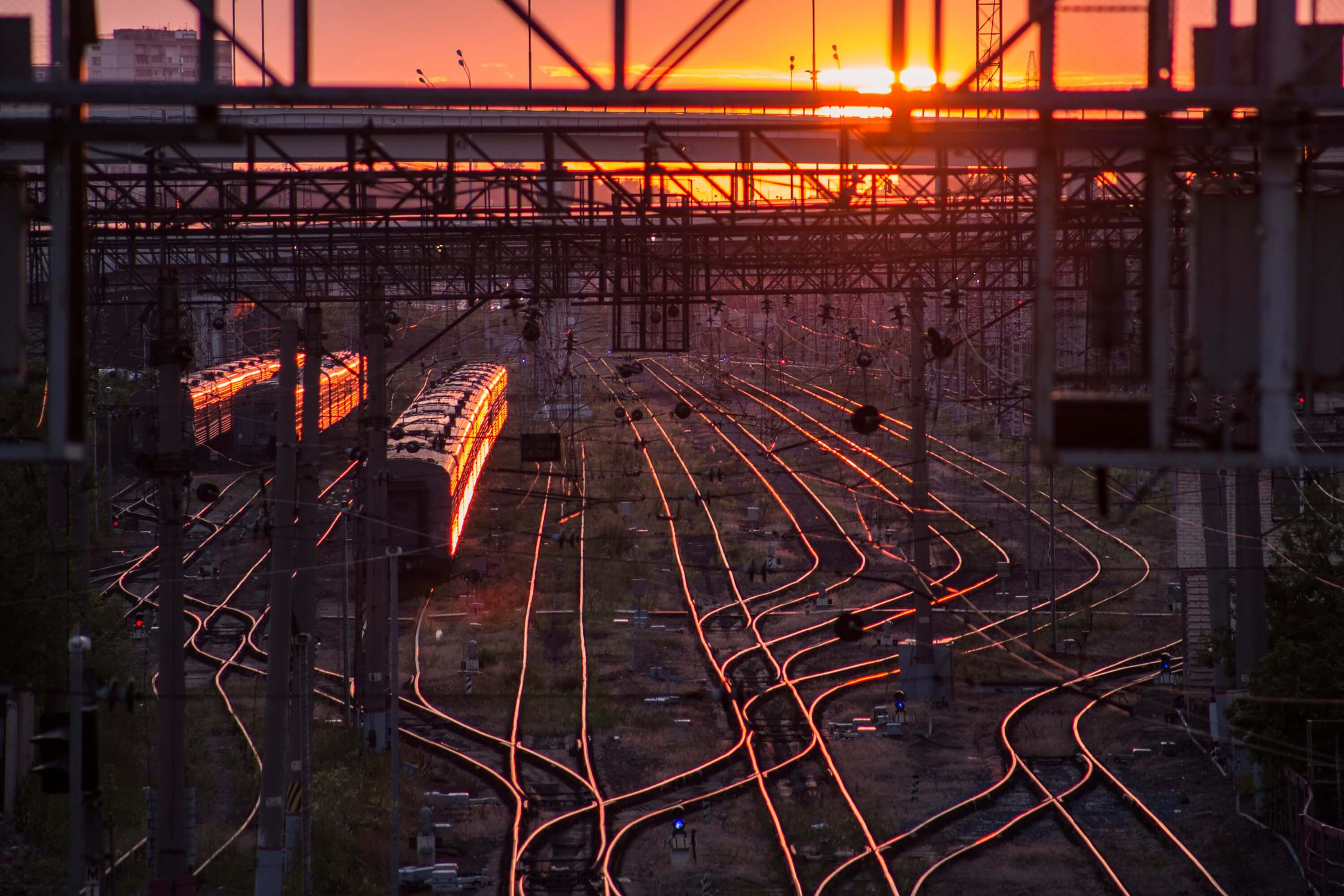

Steel rails are the literal backbone of any railway system. They provide a stable and durable path for trains, capable of supporting enormous weights and withstanding significant wear and tear. Modern rail tracks are typically made from high-carbon steel, which offers a perfect balance of hardness and flexibility. This ensures that the tracks can handle the stresses of daily train operations, resist deformation, and maintain their integrity over long periods.

There are a number of benefits of steel rails;

Steel rails can last for decades with proper maintenance, significantly reducing the frequency and cost of replacements. Think of them as the marathon runners of the infrastructure world – built to go the distance.

High strength steel can support heavy freight trains, making it ideal for both passenger and cargo transport. Like having a bodybuilder as a personal valet.

Steel’s smooth surface reduces friction and vibration, leading to a more comfortable ride for passengers and less wear on rolling stock. Your morning commute can be a glide rather than a grind.

The structural frames of locomotives and cars are made from steel to provide the necessary rigidity and strength. Without steel, these mighty machines would be more like jelly on wheels and your ride would be more of a rollercoaster.

The railway industry continuously innovates to enhance the performance and sustainability of steel. Advances in metallurgy have led to the development of high-performance steels that are stronger, lighter and more resistant to corrosion and fatigue. These improvements help in reducing overall weight and therefore leading to lower energy consumption.

While steel has many advantages, the railway industry faces challenges in terms of maintenance and cost. Steel rails and components require regular inspection and upkeep to prevent issues such as corrosion, metal fatigue and track deformation. Innovations to sensor technology and predictive maintenance are helping to address these challenges by providing real time data and enabling proactive maintenance strategies. Its like having a crystal ball, but with fewer mystics and more mechanics.

By leveraging the inherent properties of steel and embracing innovative practices, the railway industry is poised to meet the challenges of the 21st century, providing safe, reliable and eco friendly transport for generations to come. And remember, behind every great train is a whole lot of steel doing the heavy lifting – literally!